Add to Cart

ASTM A519 AISI 4130 Alloy Steel Seamless Round Tube 14x4 14x4.5 Cold Drawn Steel Tube

4130 Steel Introduce

AISI or SAE 4130 grade is a low-alloy steel containing chromium and molybdenum as strengthening agents.

The steel has good strength and toughness, weldability and machinability.

AISI/SAE 4130 grade is a versatile alloy with good atmospheric corrosion resistance and reasonable strength.

It shows good overall combinations of strength, toughness. and fatigue strength.

4130 Steel Applications

This low-alloy steel finds many applications

-as forgings in the aerospace and oil and gas industries.

-as forged valve bodies and pumps.

-as well as in the automotive, agricultural and defense industries.

Chemical Compositions

| Grade | C | Mn | P | S | Si | Cr | Mo |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0-0.035 | 0-0.040 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties

| Grade Designation | Condition | Ultimate Strength MPa | Yield Strength MPa | Elogation in 2 in. or 50 mm % |

| 4130 | SR | 855 | 689 | 10 |

| A | 552 | 414 | 25 | |

| N | 855 | 621 | 20 |

Tests we apply to the tubes

1) Chemical Composition Analysis

2) Mechanical Properties (Tensile strength, Yield strength,, Elongation, Hardness)

3) Technological Test (Flattening test, Flaring Test, Bending Test, Hydraulic pressure test)

4) Surface quality detection

5) Eddy-current examination

6) Visual test

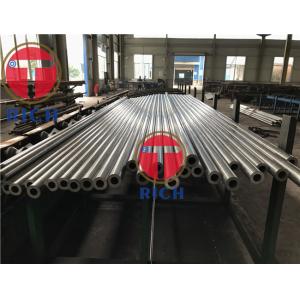

Product Display of 4130 Alloy Steel Seamless Round Tube

Manufacturing Process

Certifications

QUALITY CONTROL:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples of carbon seamless steel tube ? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us