Add to Cart

DIN EN 10130:2007-02 Cold rolled low carbon steel flat products for cold forming – Technical delivery conditions

This European Standard applies to cold rolled uncoated low carbon steel flat products in rolled widths equal to or over 600 mm for cold forming, with a minimum thickness of 0,35 mm and, unless otherwise agreed at the time of inquiry and order, equal to or less than 3 mm, delivered in sheet, coil, slit coil, or cut lengths obtained from slit coil or sheet.

It does not apply to cold rolled narrow strip (rolling width < 600 mm) nor to flat cold rolled products for which there is a specific standard, in particular the following:

— cold rolled non-grain oriented magnetic steel sheet and strip (EN 10106);

— semi-processed steel strip for the construction of magnetic circuits (EN 10126 and EN 10165);

— blackplate in coils (EN 10205);

— cold rolled flat products in high yield strength steels for cold forming (EN 10268);

— cold rolled uncoated non-alloy mild steel narrow strip for cold forming (EN 10139);

— cold rolled low carbon steel flat products for vitreous enamelling (EN 10209).

Size:

OD 4.6-10.6mm

WT 0.35-1.0mm

Length 0.6m or according to customer's request

Application: For automobile and refrigeration industry

| Steel name | Steel number | Classification according to EN 10020 | Surface quality | Absence of stretcher strain marks |

| DC01 e | 1.0330 | Non-alloy quality steel f | A | - |

| B | 3 months | |||

| DC03 | 1.0347 | Non-alloy quality steel f | A | 6 months |

| B | 6 months | |||

| DC04 | 1.0338 | Non-alloy quality steel f | A | 6 months |

| B | 6 months | |||

| DC05 | 1.0312 | Non-alloy quality steel f | A | 6 months |

| B | 6 months | |||

| DC06 | 1.0873 | Non-alloy quality steel | A | No limit |

| B | No limit | |||

| DC07 | 1.0898 | Non-alloy quality steel | A | No limit |

| B | No limit |

| Steel name | Re a | Rm | A80 b | r90 c d | n90 c | Ladle analysis chemical composition | ||||

| MPa | MPa | min. % | min. | min. | C max. % | P max. % | S max. % | Mn max. % | Ti max. % | |

| DC01 e | -/280 g i | 270/410 | 28 | - | - | 0.12 | 0.045 | 0.045 | 0.60 | - |

| DC03 | -/240 g | 270/370 | 34 | 1.3 | - | 0.10 | 0.035 | 0.035 | 0.45 | - |

| DC04 | -/210 g | 270/350 | 38 | 1.6 | 0.180 | 0.08 | 0.030 | 0.030 | 0.40 | - |

| DC05 | -/180 g | 270/330 | 40 | 1.9 | 0.200 | 0.06 | 0.025 | 0.025 | 0.35 | - |

| DC06 | -/170 h | 270/330 | 41 | 2.1 | 0.220 | 0.02 | 0.020 | 0.020 | 0.25 | 0.3j |

| DC07 | -/150 h | 250/310 | 44 | 2.5 | 0.230 | 0.01 | 0.020 | 0.020 | 0.20 | 0.2j |

| NOTE: 1 MPa = 1 N/mm 2. | ||||||||||

| a The values of yield strength are 0.2 % proof strength for products which do not present a definite yield point, and the lower yield strength ReL for the others. When the thickness is less than or equal to 0.7 mm and greater than 0.5 mm, the value for yield strength is increased by 20 MPa. For thicknesses less than or equal to 0.5 mm, the value is increased by 40 MPa. h For design purposes the lower limit of Re for grade DC06 may be assumed to be 120 MPa and | ||||||||||

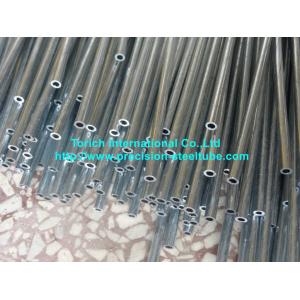

Product Pictures:

Company Introduction:

Quality Control:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

FAQ:

A: A professional steel pipes materials inventor, manufacturer and solution provider

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us.