Add to Cart

Wear Environment Alloy Steel Pipe Alloy 6B Cobalt - Based PED Certification

Alloy Steel Pipe Alloy 6B cobalt-based alloy

Alloy 6B is a cobalt-based alloy for wear environment, anti-seizure, anti-wear, anti-friction. It has a low coefficient of friction, which can make sliding contact and other metals and no wear in most cases. Even without lubricant, or cannot use lubricant applications, Alloy 6B minimizes scuffing and wear. Alloy 6 B wear-resisting performance is inherent, don't have to rely on cold working or heat treatment, which will reduce the workload and subsequent heat treatment processing cost. Alloy 6B withstand cavitation, impact resistance, thermal shock and a variety of corrosive media, and in the red hot state, the alloy 6B maintaining high hardness ,while after cooling they can restore the original hardness. So in an environment of both wear and corrosion, Alloy 6B is very practical. It can also be used in the manufacture of valve parts, pump plunger, the steam engine corrosion resistance, high temperature bearings, valve stem, food processing equipment, needle valve, hot extrusion die, molding grinding, etc.

Chemicial Composition of Alloy 6B:

| Chemical Composition | |||||||

| Ni | Cr | Fe | C | Mn | Mo | W | Co |

| ≤3% | 28%-32% | ≤3% | 0.9%-1.4% | ≤2% | ≤1.5% | 3.5%-5.5% | Margin |

Mechanical Properties for Alloy 6B:

| Mechanical Properties | |

| Tensile Strength | 999.74 MPa |

| Yield Strength | 620.53 MPa |

| Elongation after fracture | 12% |

| Hardness | Rockwell C36 |

Physical Properties of Alloy 6B:

| Physical Properties | |

| ρ | 8.387g/cm³ |

| C(@72℉) | 422.87 J/(kg·K) |

| coefficient of thermal conductivity(32-212℉) | 178.22 W/(m·K) |

| Resistor(68℉) | 546 Ω |

| Melting Temperature Range | 2310-2470 ℉(39778.2-42533.4℃) |

| electrical conductivity(compare with Copper) | 1.90% |

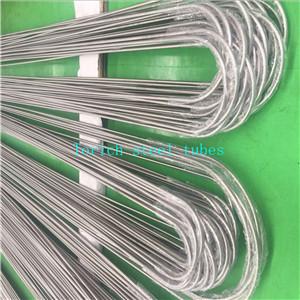

Production Picture:

Packing Picture: